Electrical equipment failure can be one of the most costly mistakes for a business. Facilities that rely on large machines to power their space can spend tens of thousands of dollars on a repair when something fails. The best way to prevent such an expensive error is to avoid equipment failure through routine maintenance and care. So let’s check out the best tips for preventing electrical equipment failure.

Tips for Preventing Electrical Equipment Failure

When is the last time you had your large electrical equipment inspected? Your Pico Rivera electrician wants you to get the best tips for preventing electrical equipment failure so you can save thousands while keeping your business running smoothly.

Why Equipment Fails

Avoiding equipment failure is impossible when you don’t know what causes the error in the first place. That is why it is so crucial that you familiarize yourself with the biggest causes of electrical equipment failure so you can assess whether your current facility is at risk. Common causes include:

- Collision with other equipment

- Added moisture or wetness to the machinery

- Loosened parts that weaken connections over time

- Short-circuiting

- Foreign objects lodged in the machine

- Disturbance in the powerline

- Power capacity overload

- Dirt, oil, or dust accumulation

It may be obvious how the majority of these causes of equipment failure can be avoided. It is still important to invest in a more regulatory maintenance schedule to avoid all chances of error. Your local technicians will help you figure out the best way to prevent electrical system failure.

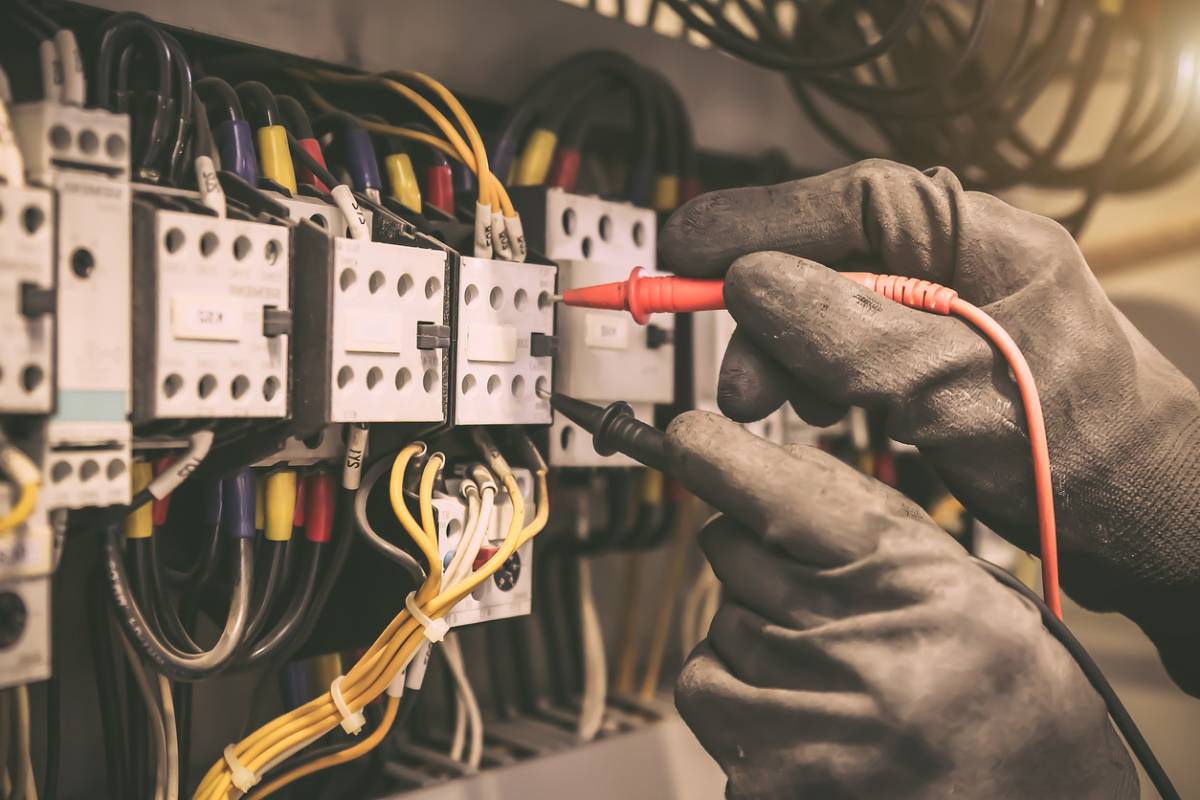

The Critical Maintenance Process

There are several major types of maintenance that we recommend for you to properly take care of your electrical equipment, avoid damage, and prevent electrical fires.

Clean Your Systems

You should always be cleaning your electrical systems when they are in use. Schedule some time once or twice a day to keep your machines free of dust and dirt. Don’t use that space for storage or other types of cleaning as it increases the risk of dust. Make sure all of your equipment is in a dry and sanitary space. Vents should move unobstructed and all connections should prove secured to prevent loose parts.

Prevent Overheating

Overheating is a common cause of electrical equipment failure. You can reduce the risk of overheating by regularly changing your filters and maintaining all fans and blowers inside the unit. If a cooling component is in disrepair, it can cause the entire machine to overheat fairly quickly. Make sure the room the equipment is stored in can maintain a regulated temperature as well.

Tighten Loose Parts

Over 30% of electrical equipment problems come about as a result of loose connections. Whether wired connections are weakening or bolts are coming loose from the machinery, you must stay on top of these mechanical needs. Periodically check the connections on your equipment to make sure everything is still tight. Consult with your manufacturer’s instructions or order an imaging test to properly check for loose connections.

The Final Step – Consult a Professional

You can perform a lot of repair and maintenance tasks on your own, but any major issues with your electrical equipment must be handled by a professional. Make sure that you get in touch with your local certified electricians to schedule a regular maintenance checkup. You can also order special tests and invest in expert repairs that will get your equipment up and running like new.

Give Your Machines a Good Tune-Up Today!

Handling electrical equipment can be a handful. It’s important that you stay up-to-date on the maintenance needs of your machines. The biggest pillars of maintenance are to keep your machines clean, dry, and tightly connected. If you are having trouble figuring out where to begin, get in touch with your top-rated industrial electrician in Pico Rivera today for an individual consultation.